TEL:18039588280 / 18630887202

Flange Butterfly Valve

Actuator type: Worm Gear

End Connection: Flange

Stem position: Double Offset

Body Materials: cast steel, stainless steel

Seat Material: stainless steel

Pressure: PN 10 / PN 16/PN25/PN40

Suitable temperature:– 10 ~ 80℃

Disc type: Ductile Iron

Size Range: DN150-DN2000

Design standards: EN593

Face to Face dimension: EN 558-1, Series 14

ISO 5752, Series 14

ISO 5752, Series 13

Flange standard: EN1092/BS4504 (DIN2501)

ASME B16.5 Class 150

Applicable medium: Industrial water, Sewage, Low Corrosive Liquids

Package: wooden case with plastic layer, wooden pallets with plastic layer, steel crates.

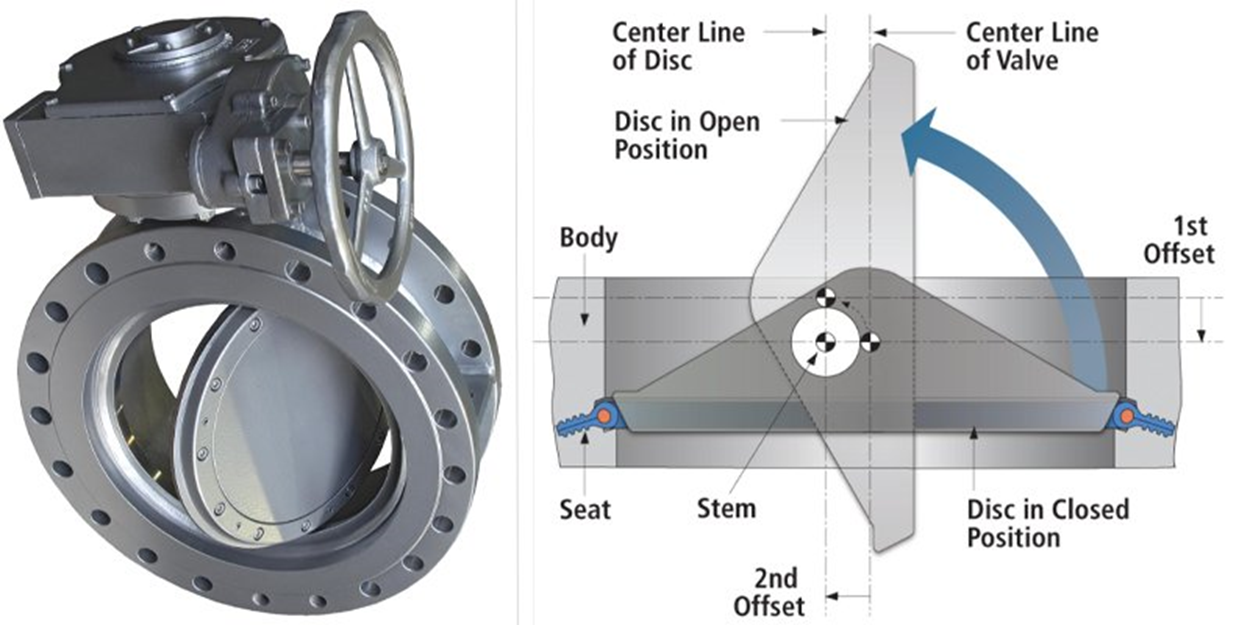

1. Introduction

The double eccentric butterfly valve belongs to the family of the offset butterfly valves. This valve has two stems offset from the center:

The axis of the shaft is behind the centerline of the sealing point of the disc to the seat.

The axis of the shaft is eccentric to the center of the valve/pipeline.

This design creates a cam action during operation to lift the seat out of the seal and reduce the friction during the first 10 degrees of opening and final 10 degrees of closing. Thus, compared with the zero offset butterfly valve, this double offset butterfly valve offers longer life by reducing contact between valve, discs, and seats. For this reason, the double eccentric butterfly valve is ideal for operations that involve high pressures and particulate fluids.

For these applications, the flange connection and lug connection are more suitable as they offer a more firm and steady connection for high-pressure applications.

In terms of the types of the seat design, there are Metal Seated Offset Butterfly Valve and Soft Seated Offset Butterfly Valve: compared with rubber lined butterfly valve, the metal seat double offset butterfly valve withstands a higher temperature and pressure.

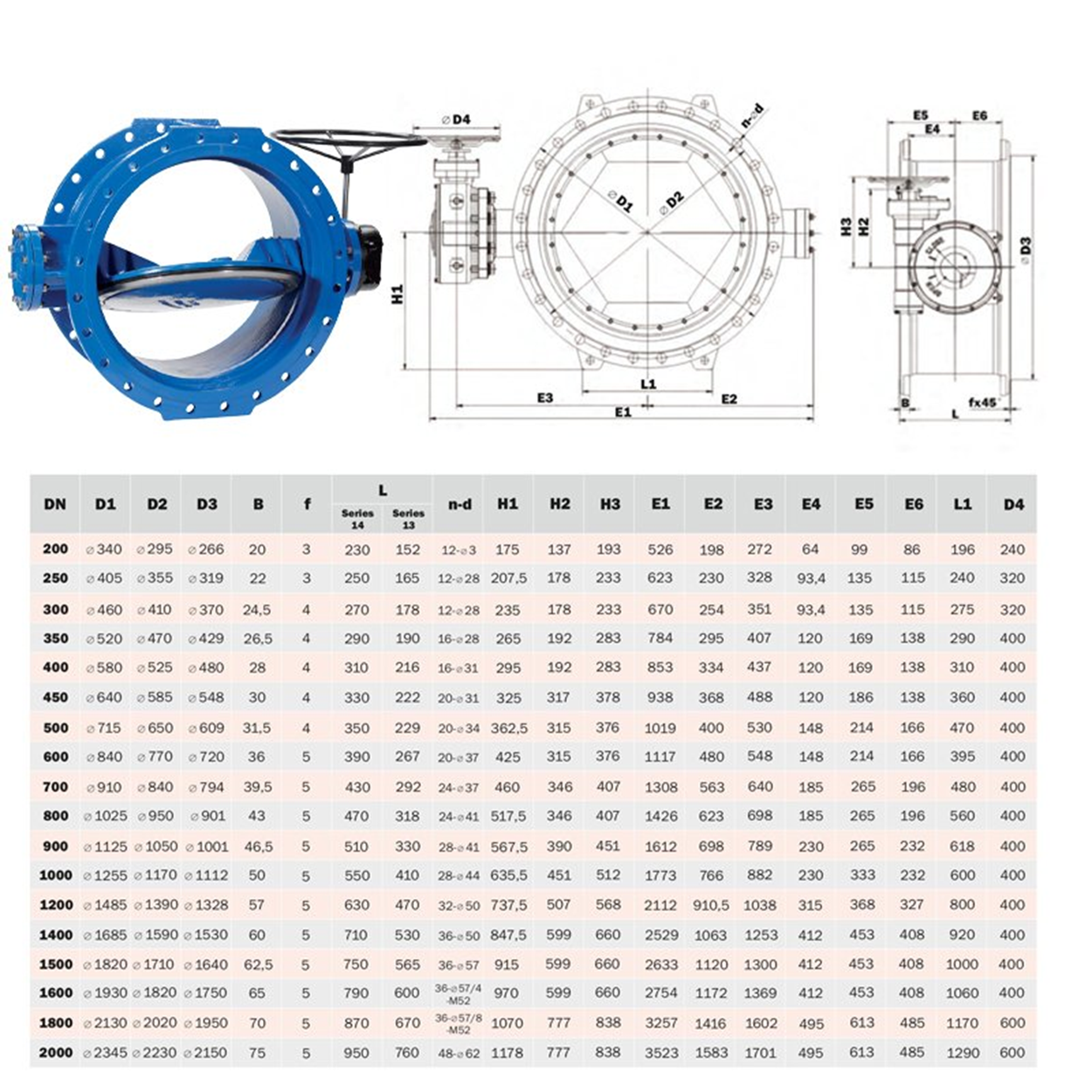

2. Specifications

3. Applications

As we mentioned before, this Flange Style Double Offset Butterfly Valve is a high-performance butterfly valve, which is suited for high-pressure applications, such as liquids and gasses in oil and gas processing, power, marine, chemical, and petrochemical industry, etc.

Contact Us

Tel:18039588280 / 18630887202 / 022-65522015

Whatsapp:008618039588280

Wechat:18039588280

mail:sales@www.valve-victory.com

Web:www.valve-victory.com